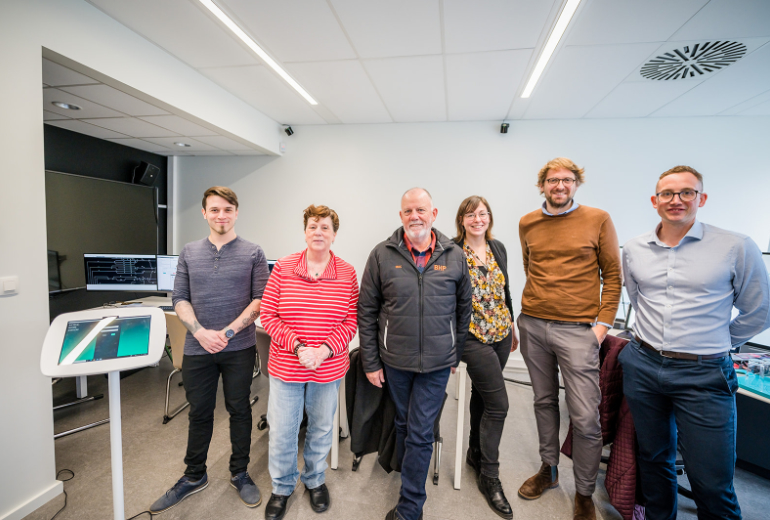

Transurb welcomed one of its Australian partners, BHP, in its offices last week for Factory Acceptance Tests. The happy and fruitful collaboration reached an important milestone in the project, and will soon be followed by a first shipment of the solution.

Missing piece

BHP is one of the world’s largest miners and operates around 1.000km of track in Western Australia near Perth. They have launched a Rail Technology Programme to improve the safety, cost and capacity of their rail network.

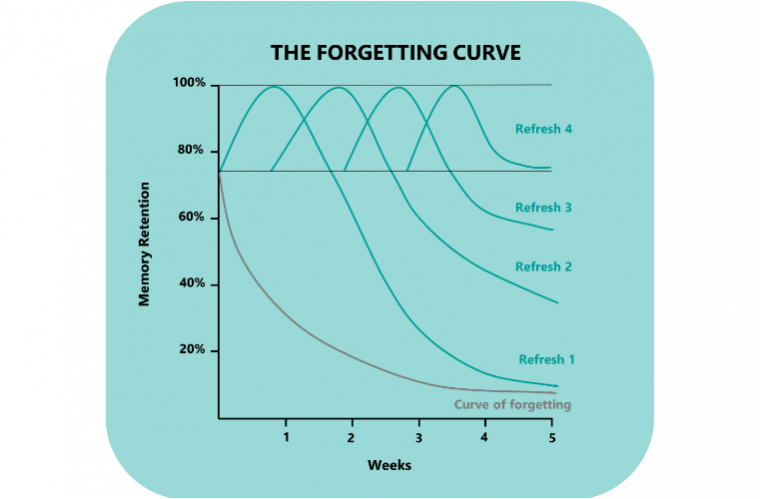

As part of this programme, and especially since such large-scale operations can make effective training as well as safety challenging, they are in need of an appropriate training tool for their Rail Management System (RMS). The problem is, like for many other operators, that the system of the Centralised Traffic Control (CTC) of the manufacturer has not been developed for training purposes; hence the challenge to give training sessions with these test benches.

BHP therefore partnered with Transurb to tackle this missing piece in the picture of Rail Control Training and ordered a Rail Control Simulator which consists of 9 ATS Rail Control Simulator workstations and 9 Mobile Work Stations (MWS).

“A powerful training tool”

Considering that Transurb has been developing a particularly modular and intuitive simulation software for over 20 years, we embraced the opportunity to develop our first Rail Control Simulator.

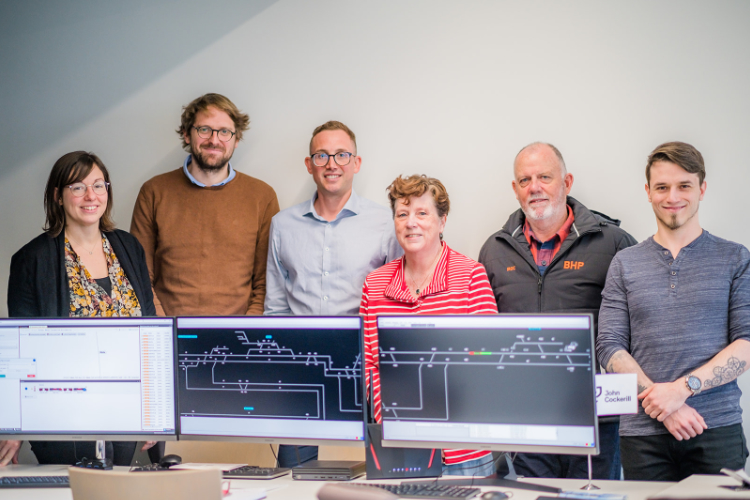

From the configuration of autonomous and controllable trains to the activation of train paths, track objects and failures, our software named R³ – for Real Rail Road – already possessed the required features to simulate a complex and real-like network and traffic.

Transurb is adapting its software to simulate Alstom’s ATS as well as the integration of the Mobile Work Station. The simulators will reproduce 400km of track with a controlled section containing CBTC and ATP, and a section without signalling – an uncontrolled section –, also named dark territory.

It is, as enthusiastically expressed by our client, a “powerful training tool” with which all types of scenarios can be quickly and realistically reproduced, and provide an immersive experience for their Operators.

Successful collaboration

BHP’s simulated solution is being developed parallel with Alstom’s software, which means our SCRUM methodology is more than necessary for this project; this agile way of working makes it possible to easily adapt our software to the evolution of Alstom’s, and to provide flexibility with our production cycles.

But more importantly, such a smooth and successful collaboration would not be possible without partners such as BHP; we heartily thank them for their valuable and considerable input, as well as their trust in us.

Nicholas Howard, System Project Engineer at BHP, testifies:

The team has been highly responsive and dedicated to providing our Rail Control Training Simulator. Their engagement and commitment to customer satisfaction has been excellent, and although at the early stages of the project, truly shows in the quality of the team’s work. I have been thoroughly impressed with their attention to detail and the willingness to go above and beyond to ensure the product meets ours needs.

— Nicholas Howard